In an industrial environment, the ability to access accurate data in real time is critical to making rapid and effective decisions. Moxa's remote I/O solutions aim to provide reliable connectivity and ease of installation, supported by built-in intelligence that results in more efficient data collection and analysis. These industrial devices are helping organizations work smarter, not harder, while making accurate field data accessible and actionable.

Watch How It Works

Curious how Moxa remote I/Os support your operations in the field? Check out the following video to see them in action, streamlining data capture and decision-making for teams who need reliable performance from anywhere.

What Makes Moxa Remote I/Os a Smart Choice

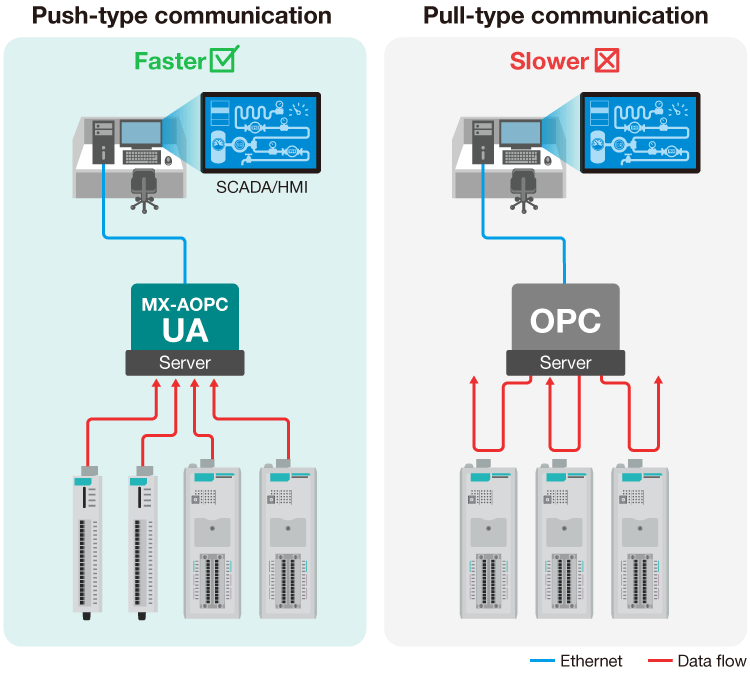

Designed for Proactive Data Delivery

Moxa remote I/Os are designed with event-driven push technology and the built-in Click&Go Plus Logic to eliminate unnecessary polling, reduce system load, and improve IT/OT convergence.

Easy to Use

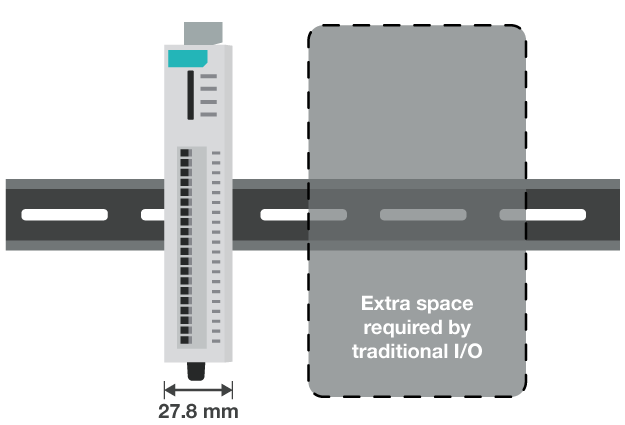

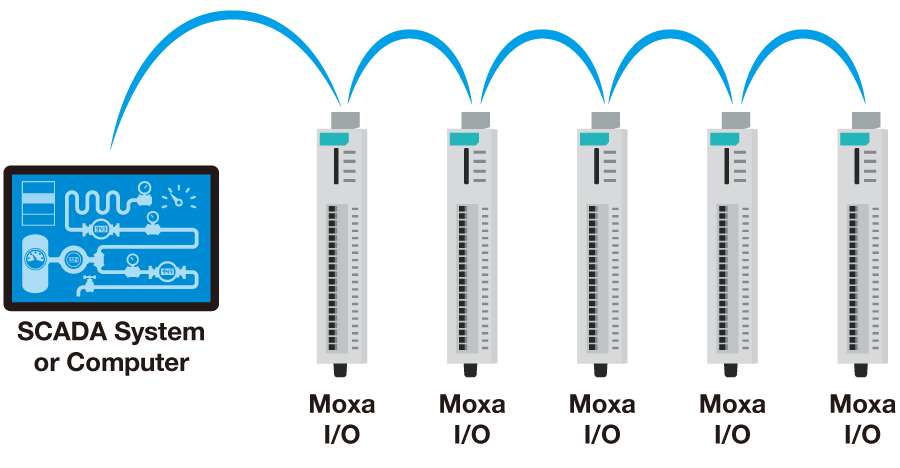

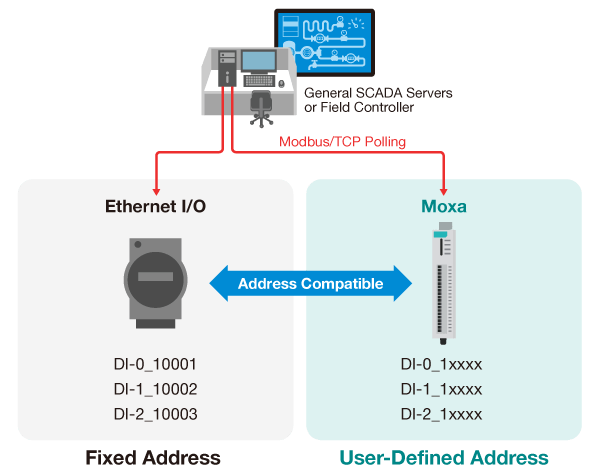

Moxa focuses on simplicity of deployment with optimized wiring design, daisy-chainable Ethernet interfaces, and configurable Modbus connectivity, allowing remarkable efficiencies in system integration.

Reliability

Moxa's remote I/Os are made for tough environments, from the manufacturing floor to the outdoors, to continue to operate reliably.

Moxa's remote I/Os are designed to withstand challenging conditions, whether they are being used on a factory floor or in outdoor systems.

They have an extensive operating temperature range, allowing them to operate in extreme conditions without issue. Some models, such as the ioLogik R1200, offer better noise immunity for dependable RS-485 communication.

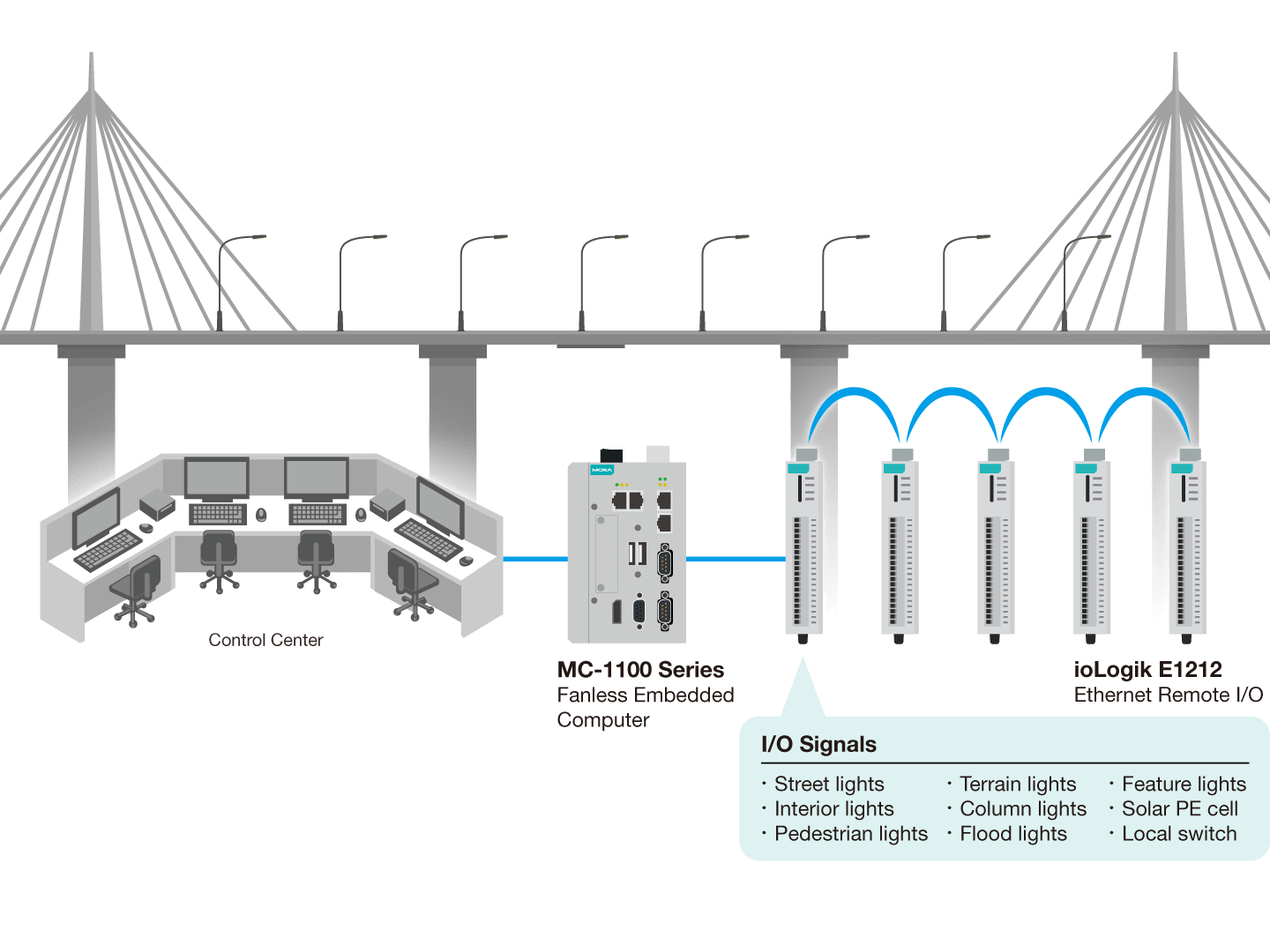

Intelligent Transportation

Whether it is bridges or airports, Moxa’s remote I/Os help control outdoor applications such as lighting, roadside cabinets, and field devices in a reliable way, with a compact and rugged design for challenging environments.

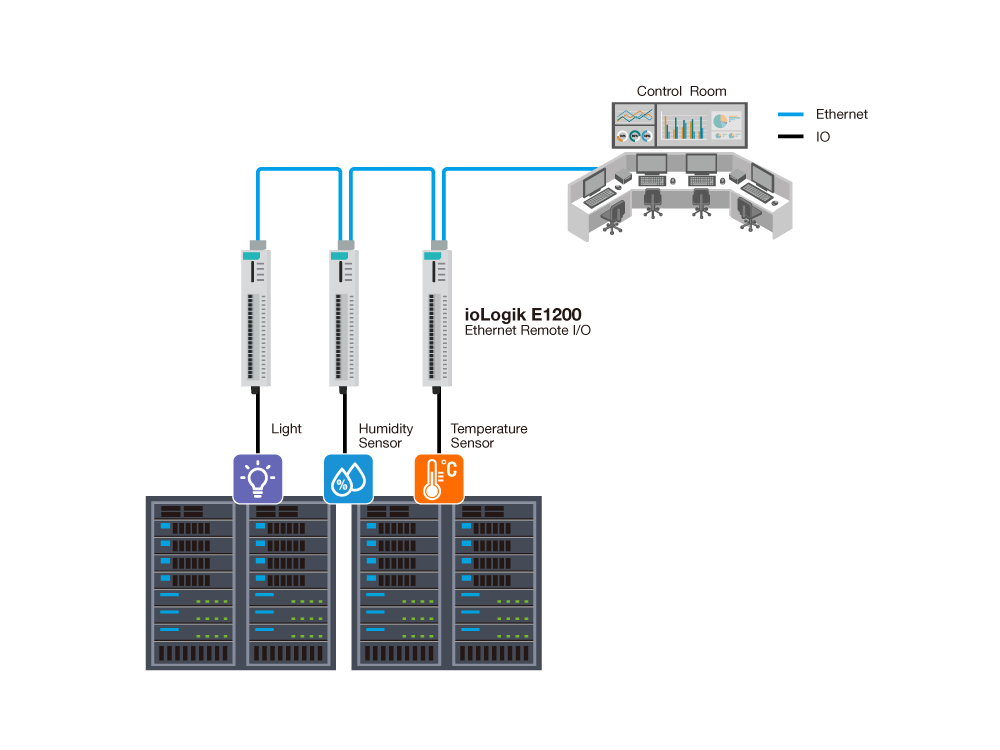

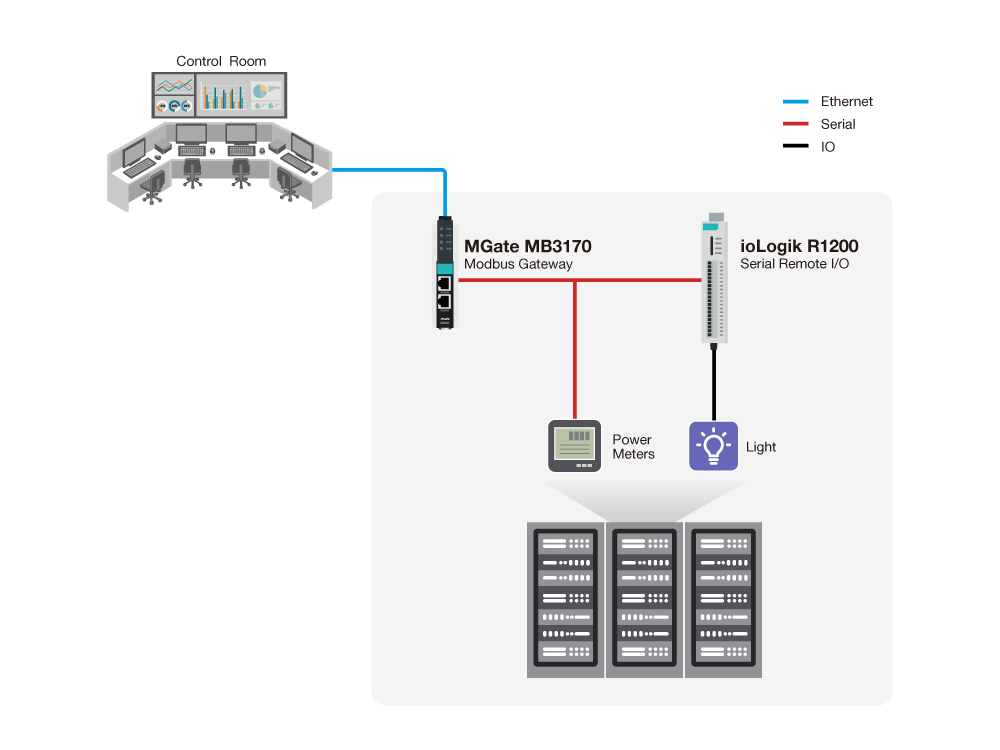

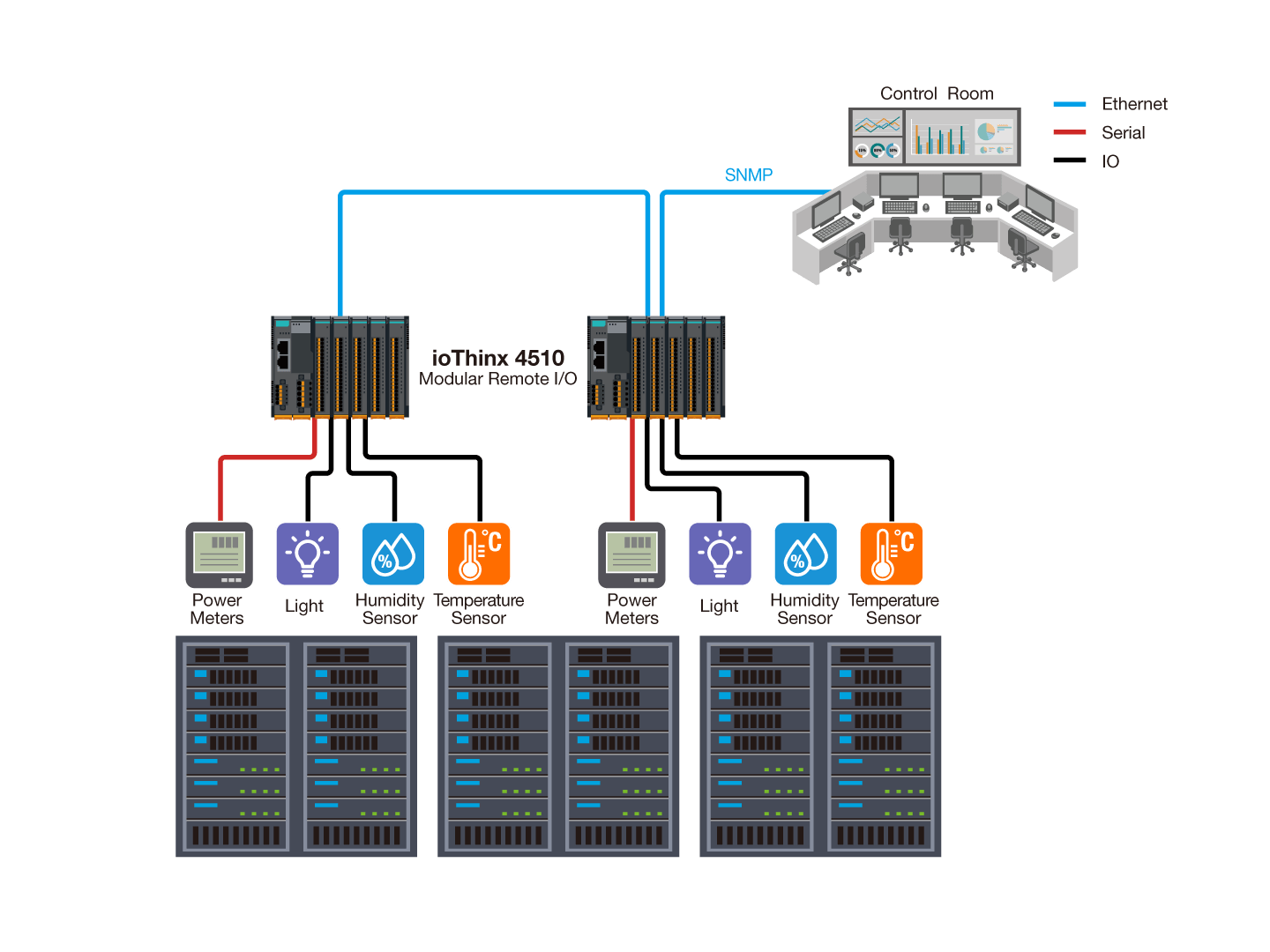

Data Center

From monitoring temperature to integrating power meters or replacing legacy systems, Moxa remote I/Os provide flexible and compact solutions that connect to IT-based systems using either Modbus or SNMP.

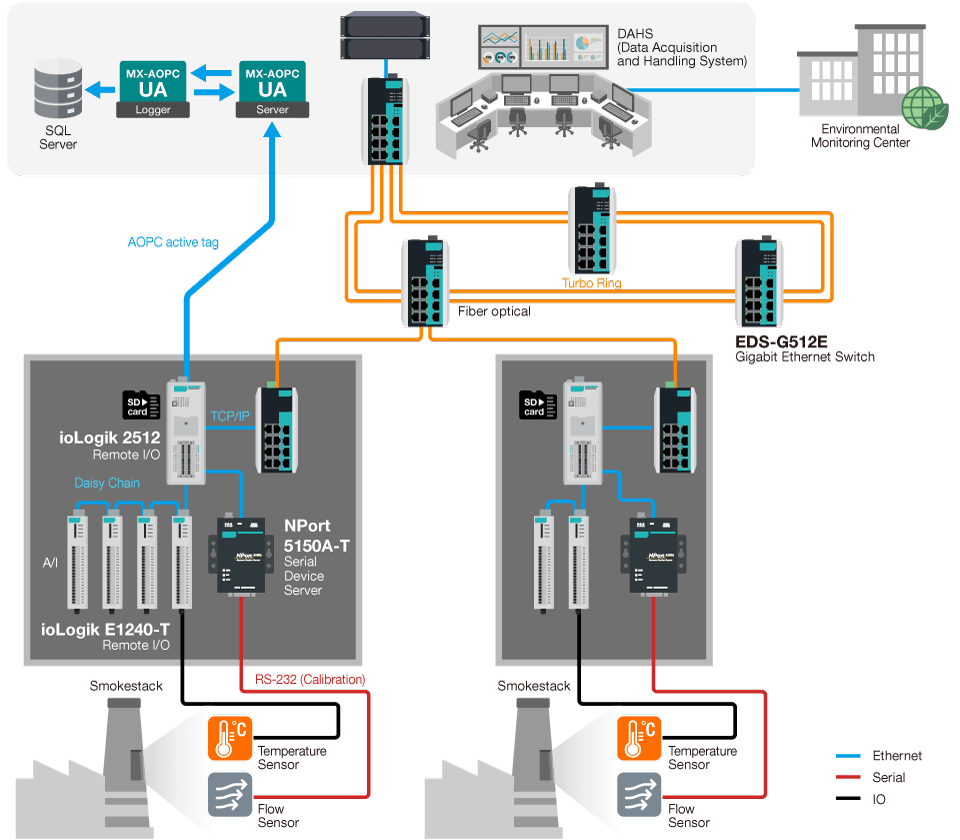

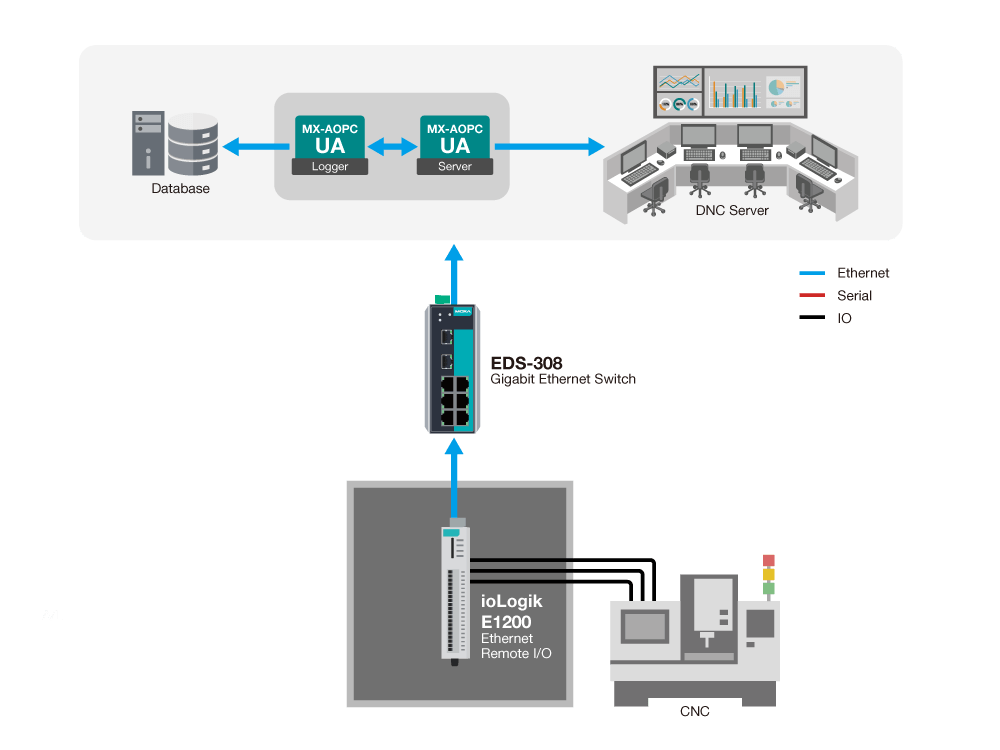

Manufacturing

From factory emissions to machine status signals, Moxa remote I/Os enable digitalized operations with simple installation, a varied selection of I/O, and integration to an MES or SCADA system without a hassle.

Choose the Right Remote I/O for Your Needs

ioLogik E1200 Series

Effortless installation

Compact front-wiring design streamlines setupSmart networking

Built-in 2-port Ethernet switch for daisy-chain connectivitySeamless IT integration

Supports Modbus TCP, RESTful API, and SNMPProactive data reporting

Real-time active communication via MX-AOPC UA Suites

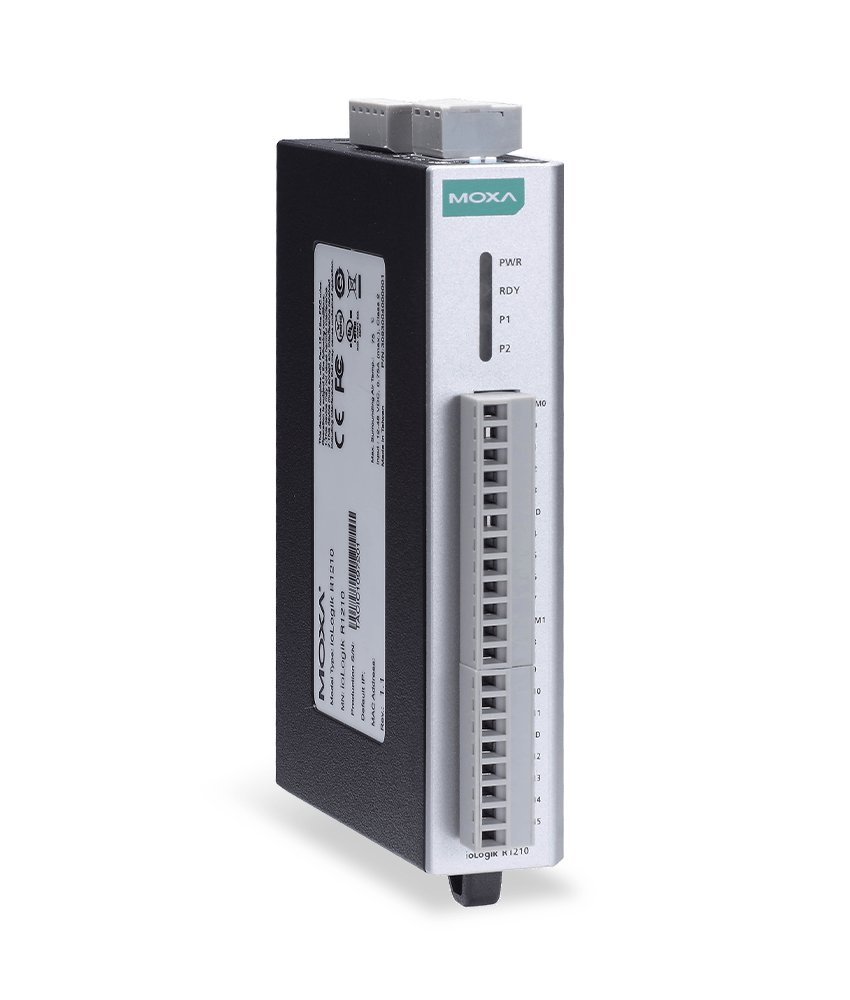

ioLogik R1200 Series

Fast and easy deployment

Compact front-wiring design for simplified installationSuperior stability

137% wider common mode voltage enhances RS-485 reliabilityReliable connectivity

Dual RS-485 or repeater mode for flexible wiring and data flow continuityHassle-free maintenance

Configure communication parameters and upgrade firmware via USB or RS-485

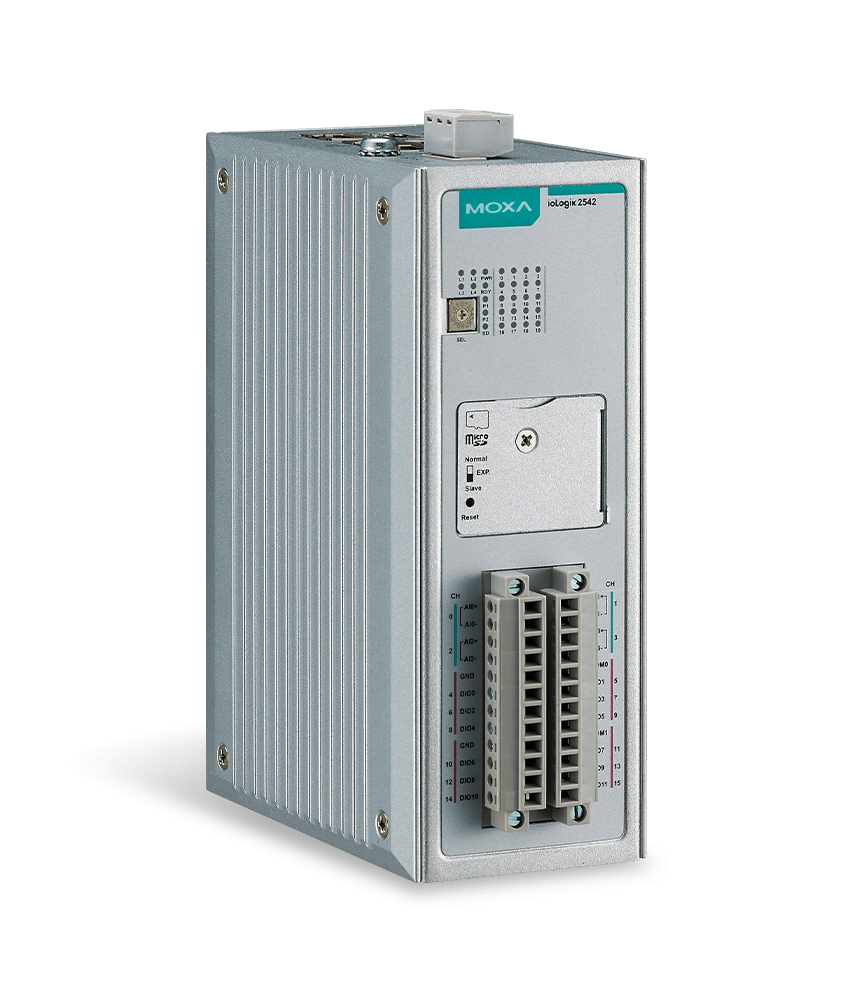

ioLogik 2500 Series

Edge Intelligence

Built-in Click&Go Plus logic enables local decision makingHighly scalable

Expandable with up to 8 additional ioLogik E1200 unitsFlexible connectivity

4-port Ethernet switch and dual serial ports for seamless integrationReliable data continuity

Auto lost data recovery via MX-AOPC UA Suites

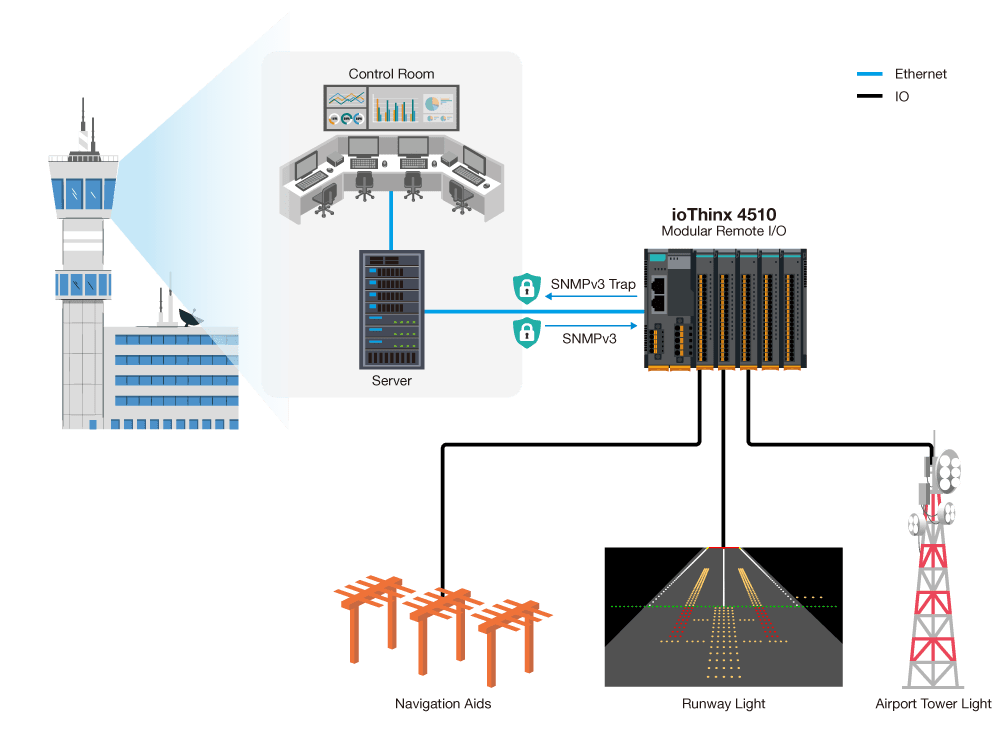

ioThinx 4510 Series

Quick installation

Tool-free setup and auto reconfiguration reduce downtimeFlexible expansion

Supports up to 32 modules for scalable applicationsMultiple connectivity options

2-port Ethernet switch and 3-in-1 serial port for various industrial setupsIT-ready design

Supports Modbus TCP, RESTful API, MQTT, and SNMPv3 for modern IIoT integration

Where Remote I/Os Make a Difference

Intelligent Transportation

Moxa’s remote I/Os offer reliable control for outdoor systems like lighting, roadside cabinets, and field devices, ranging from bridges to airports, with a compact, rugged design built for tough environments.

Data Center

Whether it's for temperature monitoring, integrating power meters, or upgrading legacy systems, Moxa remote I/Os deliver flexible, space-saving solutions that effortlessly connect to IT systems via Modbus or SNMP.

Manufacturing

From factory emissions to machine status signals, Moxa remote I/Os drive digital transformation with easy installation, versatile I/O support, and smooth integration with MES or SCADA platforms.

Selection Guide

| Remote I/Os |

|---|

| I/O |

| Front-end logic |

| Ethernet port |

| Serial |

| Northbound protocol |

| Active protocol |

| Southbound protocol |

| Operating Temp. range |

| Standards and Certifications |

ioLogik E1200 Series

|

ioLogik R1200 Series

|

ioLogik 2500 Series

|

ioThinx 4510 Series

|

|---|---|---|---|

| DI, DO, Relay, AI, AO, RTD, TC | DI, DO, Relay, AI, AO | DI, DO, AI (Relay, AO, RTD, TC expandable) | DI, DO, Relay, AI, AO, RTD, TC expandable by 45MR Series |

| - | - | Click&Go Plus | - |

| 2 | - | 4 | 2 |

| - | 2 x RS-485 | 2 x RS-232/422/485 | 1 x RS-232/422 or 2 x RS-485 |

| Modbus TCP server (slave) EtherNet/IP adapter SNMPv1/v2c RESTful API | Modbus RTU Server (Slave) | Modbus TCP server (slave) SNMPv1/v2c/v3 RESTful API | Modbus TCP server (slave) SNMPv1/v2c/v3 RESTful API via TLS |

| Moxa AOPC (Active tag) SNMPv1 Trap | - | Moxa AOPC (Active tag) SNMPv1/v2c Trap CGI command | MQTT via TLS SNMPv1/v2c/v3 Trap SNMPv2c/v3 Inform |

| - | - | Modbus TCP client (master) Modbus RTU client (master) | Modbus RTU client |

| Standard models: -10 to 60°C (14 to 140°F) Wide temp. models: -40 to 75°C (-40 to 167°F) | Standard models: -10 to 75°C (14 to 167°F) Wide temp. models: -40 to 85°C (-40 to 185°F) | Standard models: -10 to 60°C (14 to 140°F) Wide temp. models: -40 to 75°C (-40 to 167°F) | Standard models: -20 to 60°C (-4 to 140°F) Wide temp. models: -40 to 75°C (-40 to 167°F) |

| CID2, ATEX Zone 2, CE, FCC, UL | CE, FCC, UL | CID2, ATEX Zone 2, CE, FCC, UL | CID2, ATEX Zone 2, CE, FCC, UL |

*For any further information, please contact us via info@rockford-qatar.com.

-150x150.png)